factory customized Small Pond UV Sterilizer - Medium Pressure UV Sterilizer – Guanyu Detail:

Characteristics Of The Equipment

Medium pressure ultraviolet lamp tube: using medium pressure high quality imported lightsources from the United States, high power, reduce the number of lamp tube configuration, can handle large flow water. Compared with the low pressure ultraviolet lamp tube, the ultraviolet ray intensity is big, the radiation ray wavelength is wide.

Temperature probe: immediately detect the temperature of water to ensure that the equipment operates at the operating temperature of 0~45 degrees.

Temperature probe: immediately detect the temperature of water to ensure that the equipment operates at the operating temperature of 0~45 degrees.

Quartz tube: in order to better protect the ultraviolet lamp tube, each ultraviolet lamp tube will have a quartz tube outside. Therefore, the quality of the quartz sleeve largely determines the sterilization effect of the uvb sterilizer. The high-quality quartz sleeve can ensure the uv penetration rate of more than 90%.

Daily cleaning: due to the irradiation of water quality and ultraviolet light, the surface of the quartz casing will crystallize after a period of use. If the thickness of the crystal reaches a certain degree, the penetration ratio of ultraviolet ray will be affected. Therefore, the quartz casing needs to be cleaned regularly. The medium pressure uv sterilizer is equipped with an automatic cleaning system, which can automatically clean the quartz sleeve according to the reading of the uv intensity detector. During the cleaning process, the system runs normally without water cut or manual participation, which greatly reduces the workload of field personnel.

Technology Parameter

|

Equipment model |

Disinfection of power(KW) |

Flow rat(T/H) |

Size of inlet and outlet |

The power supply voltage |

|

UUVC-1/1.0KW |

1.0 |

30-40 |

DN100 |

220V50Hz |

|

UUVC-1/2.0KW |

2.0 |

60-80 |

DN125 |

220V50Hz |

|

UUVC-1/3.0KW |

3.0 |

100-125 |

DN150 |

220V50Hz |

|

UUVC-2/2.0KW |

4.0 |

130-150 |

DN200 |

380V50Hz |

|

UUVC-2/3.0KW |

6.0 |

200-250 |

DN250 |

380V50Hz |

|

UUVC-3/3.0KW |

9.0 |

250-300 |

DN250 |

380V50Hz |

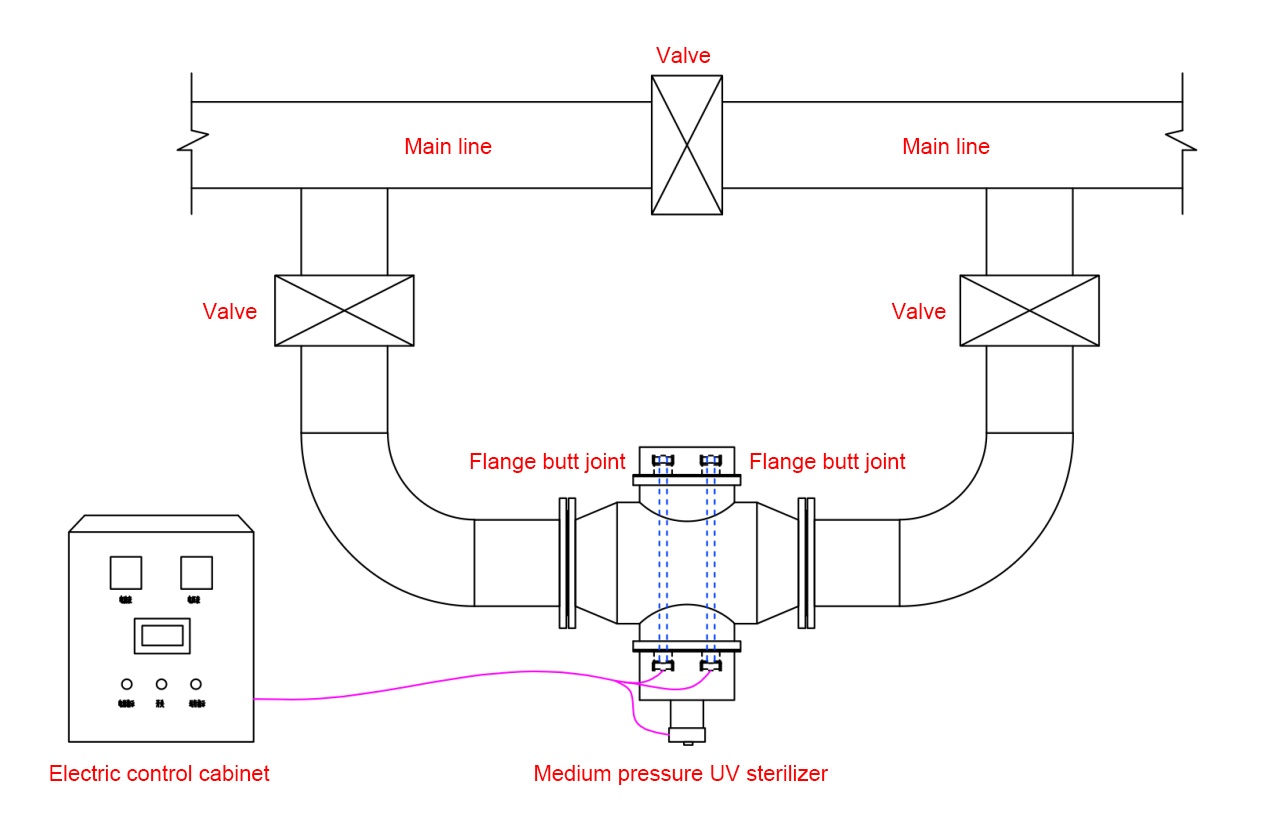

Equipment Installation Schematic Diagram

Common Troubleshooting Methods

| The fault | Why | Elimination method |

| The quartz tube is leaking at the end | 1. Quartz tube is broken; 2. The end gland is not tightened 3. Washer damage |

1. Replace the quartz tube; 2. Tighten the cover screw evenly until it is watertight, and do not over tighten it. 3.Replace the washer |

| Low bactericidal efficiency | 1. Low voltage; 2. External wall attachment of quartz tube; 3. The radiation intensity of the lamp tube is lower than 70U. 4. Reach the normal service time of the lamp tube 5. Excess of rated flow 6. Impurities, minerals and suspended substances in the water exceed the standard |

1. Adjust voltage; 2. Clean quartz tube; 3. Replace the tube. 4. Replace the tube 5. Adjust the flow or increase the equipment 6. Add filter device or increase equipment |

| Lampis not bright | 1. Dissolve broken silk and burn it off; 2. The lamp socket is not properly plugged in; 3. The plug inside the socket breaks off; 4. Whether the ballast is damaged; 5. Whether the led tube is damaged; 6. Whether the bridge is broken; 7.Lamp tube damaged |

1. Replace dissolved broken silk; 2. Plug in the socket; 3. If the insert piece is removed and welded, then welded firmly; 4. Or replace the socket 5. Any damage found must be replaced. 6. Replace the tube. |

| The power cord or plug is unusually hot and has a burning smell | Weak cable carrying capacity | Replace the cable |

Influent Quality

(drinking water) water inlet requirements

|

hardness |

<50mg/L |

The iron content |

<0.3mg/L |

|

sulfide |

<0.05mg/L |

Suspended solids |

<10mg/L |

|

Manganese content |

<0.5mg/L |

chroma |

<15degrees |

|

The temperature |

5℃-60℃ |

|

|

(sewage) inlet water requirement index

|

COD |

<50mg/L |

BOD |

<10mg/L |

|

Suspended solids |

<10mg/L |

PH |

6.0-9.0 |

|

chroma |

<30 |

turbidity |

<10NTU |

|

The water temperature |

5℃-60℃ |

|

Routine Inspection And Testing

● every 4-5 weeks after the use of the equipment, the equipment should be checked, pay attention to the following abnormal conditions

● the power cord or plug is unusually hot with a burning smell.

● welding part of the pipe, the interface part, whether the two ends of the quartz pipe leak.

● control cabinet indicator light, lamp tube is normally lit.

● low sterilization efficiency.

● other abnormal faults.

In case of any of the above situations, stop using the equipment to prevent accidents. Be sure to follow “common troubleshooting methods” to troubleshoot. If the troubleshooting still cannot be eliminated, please contact our company and its agents and resellers.

Note: blue, green and yellow colors at both ends of the tube are normal phenomena.

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of factory customized Small Pond UV Sterilizer - Medium Pressure UV Sterilizer – Guanyu, The product will supply to all over the world, such as: Casablanca, Denmark, Tunisia, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.

-

100% Original Pure Distilled Water - AOP River...

-

Professional Design Water Still Distillation Un...

-

Manufacturing Companies for Vapor Compression W...

-

OEM/ODM China Ultraviolet Water Filter - AOP C...

-

Best Price on UV Light For Small Fish Tank - U...

-

OEM China Sterile Water And Distilled Water - ...